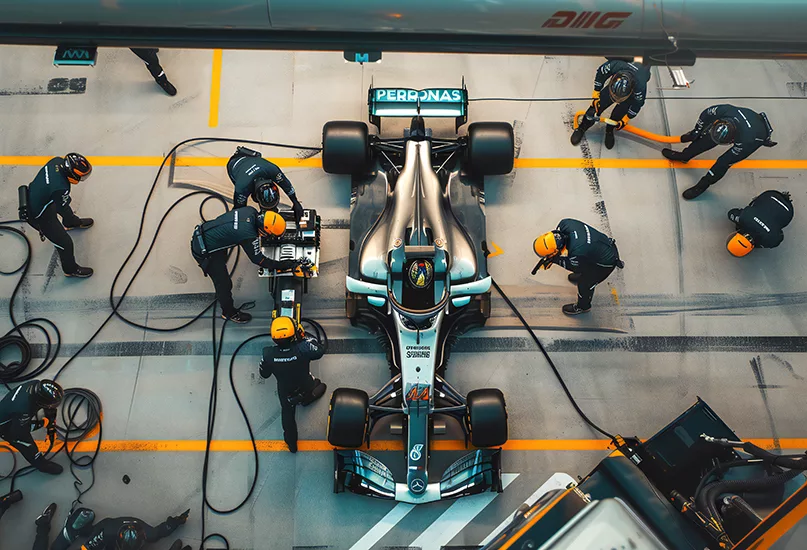

As Formula 1 accelerates towards achieving net zero by the end of the decade, we take a look at how the pinnacle of motorsport is moving around the world more sustainably than ever before thanks to innovative logistics solutions.

THE RACE TO NET ZERO

Formula 1 (F1) has always led the way in technical engineering, but there is just as much innovation going on behind the scenes in terms of travel and logistics, which are responsible for two-thirds of the sport’s carbon footprint.

Everything that F1 teams need to compete in the pinnacle of motorsport, from cars and critical equipment to spare parts, tyres, and fuel, is transported from race to race across the world.

In recent years, more sustainable logistics solutions for moving these assets between venues have been introduced as part of F1’s pledge to reach net zero by 2030.

Making these logistical modifications is no easy feat, however, given F1 is a global championship that is now racing in a record-breaking 24 countries across five continents this season.

With an unprecedented number of Grands Prix taking place in 2024, the current F1 race calendar has been built with a greater focus on regionalisation to reduce logistical burdens and the distance freight travels between events so the sport moves more sustainably to each destination.

Three races have changed position this season in pursuit of a more regionalised calendar, the most significant of which was the Japanese Grand Prix, which shifted from its traditional September slot to April, coinciding with events in nearby Australia and China to improve travel efficiencies.

Azerbaijan moved in the opposite direction as a result, whilst Qatar will now take place on the penultimate weekend of the season in early December as a stop-off from Las Vegas on the way to the Abu Dhabi finale.

Whilst travel cannot be completely regionalised due to the climatic and contractual constraints of a world championship, these amendments to the calendar have created a better flow of races in certain parts of the world and will continue to be worked on.

INNOVATIVE TRUCKING SOLUTIONS

As well as regionalising the race calendar, redesigned freight containers mean more fuel-efficient aircraft can be used to transport equipment across the planet, further lowering carbon emissions.

Innovative trucking solutions, meanwhile, have likewise been implemented on the ground to make F1’s logistical operations more sustainable.

For example, during the European leg of the 2023 season, the use of biofuel-powered trucks resulted in an 83 percent average reduction in logistics-related emissions.

This was achieved without sacrificing the high performance levels of their diesel counterparts in terms of load capacity and travel distance that teams and F1 as a whole have come to expect.

Across the nine European rounds, the vehicles travelled more than 10,600 kilometres (km) and transported 300 tonnes of vital freight per race on average.

The fleet, which will more than double in size this year from 18 to 37 trucks, runs entirely on HVO100 drop-in fuel and is additionally equipped with GPS to track consumption and optimise more efficient driving routes.

These biofuelled vehicles mark the latest innovation by F1 to introduce more sustainable logistical solutions and use the most up-to-date technologies and ways of working to ensure the delivery of events in a more environmentally-friendly manner, as part of its wider efforts to achieve net zero by the end of the decade.

Biofuel will continue to be used in 2024 and beyond, with data from this summer providing invaluable insights as further opportunities and sustainable innovations are explored.

REMOTE BROADCASTING

The way Grands Prix are broadcast has been changed in recent years by switching to a remote production model.

Hundreds of hours of TV coverage per season is captured by several pieces of equipment at each race, including numerous cameras, microphones, and cables, providing live action to millions of viewers around the world.

Remote operations have seen F1 transition from a single circuit-based Broadcast Centre into a smaller Event Technical Centre (ETC), which is about half the size, and a Remote Technical Centre (RTC) in the UK, where TV production now takes place rather than at the track.

A large part of the technical set-up required to run and broadcast each race weekend is therefore now operated remotely from the UK, rather than having to transport everything to each venue.

ETC is deployed on-site at every event and acquires content, data, and feeds which are sent back to RTC. The majority of processing and publishing systems have also moved to RTC, including replays, remote racking, and colour correction of all broadcast cameras.

This transition has enabled a reduction in both technical cargo shipments and the number of personnel taken to every track, making a step-change impact on F1’s logistics footprint over a whole season.

F1 therefore evidently remains steadfast in its commitment to the green agenda and will continue to explore further sustainable logistics initiatives as it approaches the net zero chequered flag in 2030.